- Exterior Panelization

- Light Gauge Interior Panels

- Panelmax: furr downs, mullcaps, inside/outside drywall corners

- Design: Fully coordinated panels & BIM Modeling

- Prefabricated in-wall blocking

- Roof/floor joist sections

- Non-loadbearing & loadbearing

- Bypass framing

Prefabrication

Prefabrication

Capabilities

Benefits

- Schedule & Timeline: Prefabrication reduces on-site construction time, allowing projects to meet demanding deadlines and fast-paced schedules.

- Quality: With components produced in a controlled environment and precision-engineered before installation, the quality of both the construction process and the finished product is elevated.

- Safety: By minimizing time spent on-site, paired with the controlled offsite prefabrication environment, exposure to safety risks is reduced.

- Customization: Prefabrication is adaptable to meet unique project specifications and design requirements, offering flexible and precise solutions.

- Experienced Team: GMi’s highly skilled team and state-of-the-art facilities ensure superior craftsmanship and efficient execution.

Case Study

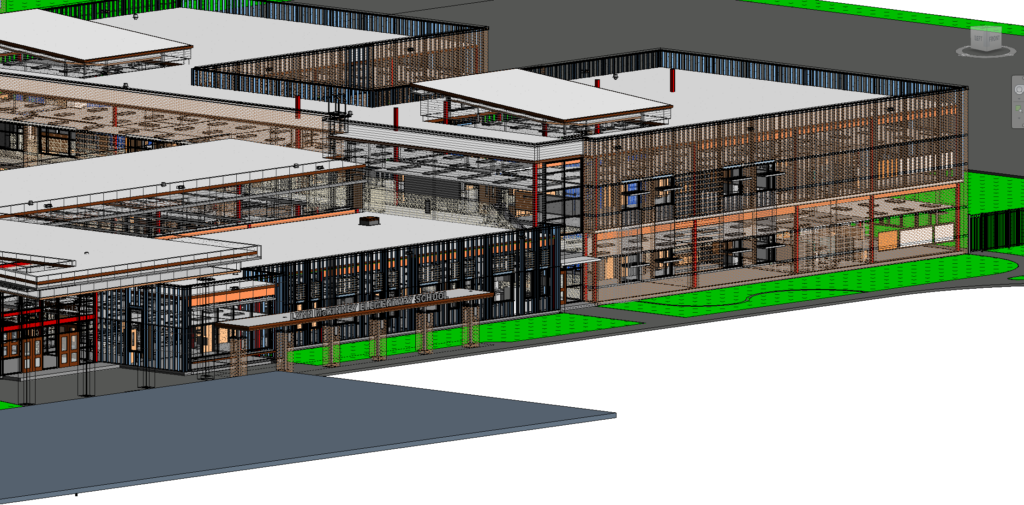

Lynn McKinney Elementary School

Lynn McKinney Elementary School, located in Aledo, TX is a ground-up two-story elementary school in Aledo, Texas. This addition to Aledo ISD increased the district’s student capacity by expanding its space for grades K-5. The school can accommodate 889 students, which will serve the expanding community for years to come.

GMi prefabricated the panels for this project in our offsite facility.

Interested in more Education projects GMi has worked on? View here!

The Aledo ISD #7 project schedule was originally set for 12 months, with the school planned to open for the 2024-2025 school year. To meet this fast-paced deadline, GMi recommended using prefabricated exterior wall panels to the general contractor, Core Construction. After careful coordination, it was agreed that 50% of the exterior façade, excluding the storm shelter, would use prefabricated panels from GMi’s offsite facility in Southlake, Texas. As a result, GMi cut the 10-week framing and sheathing timeline by 60%, installing the prefabricated panels in just 15 days.

While the scheduling benefits of prefabrication are the most notable, other advantages include improved safety and quality. Offsite prefabrication allows for better control in a secure environment, reducing material handling, overhead work, and the risk of dropped object incidents. Additionally, GMi achieved 60% less time working with leading-edge fall prevention. Prefabrication also minimized variance during installation, leading to greater consistency.

For future projects, it is recommended that prefabrication be assessed as a key approach to achieving efficiency and safety.

- City: Aledo, TX

- Square Feet: 115,000

- GC: Core Construction

- Architect: PBK Architects, Inc.

- Completed: 2024

- Scope: 2-story ground up elementary school. GMi's scope included cold-formed metal framing, rough carpentry, gypsum sheathing, thermal insulation, fire and smoke protection, doors and frames, non-structural metal framing, gypsum board, acoustical ceilings, tectum panels, specialty ceilings, and acoustic wall panels.

Interested in more prefabrication projects GMi has worked on?